/about/butt_joint-588e41253df78caebc22cb8f.jpg)

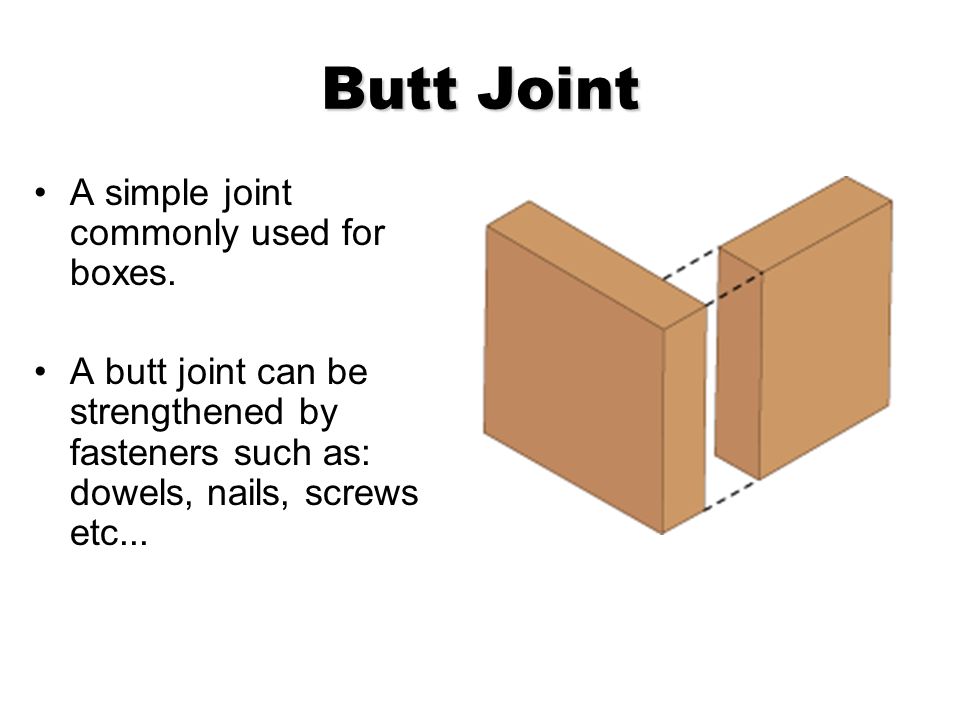

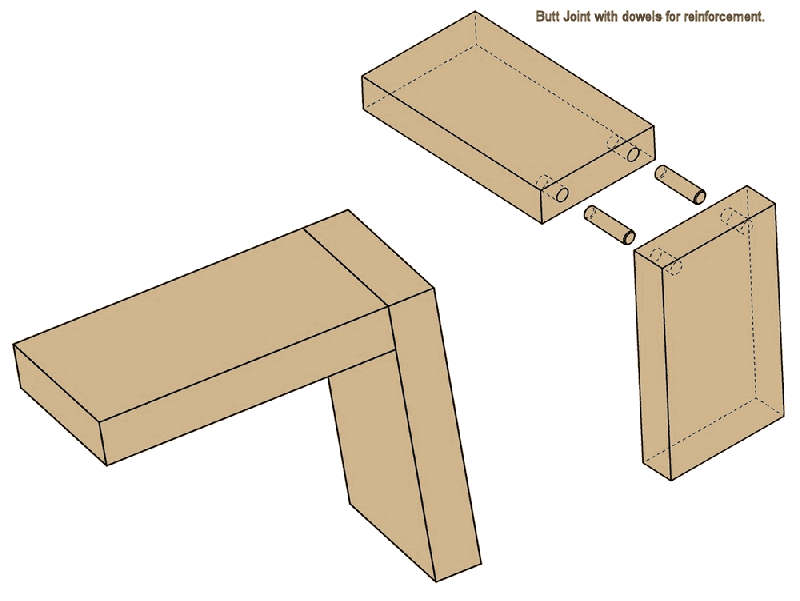

Butt joints are the easiest of all to make. Wood is butted face to edge or end to edge and nailed, screwed or dowelled together. End to edge joints can be joined with corrugated fasteners.

Take a comprehensive look at the most common wood joints.

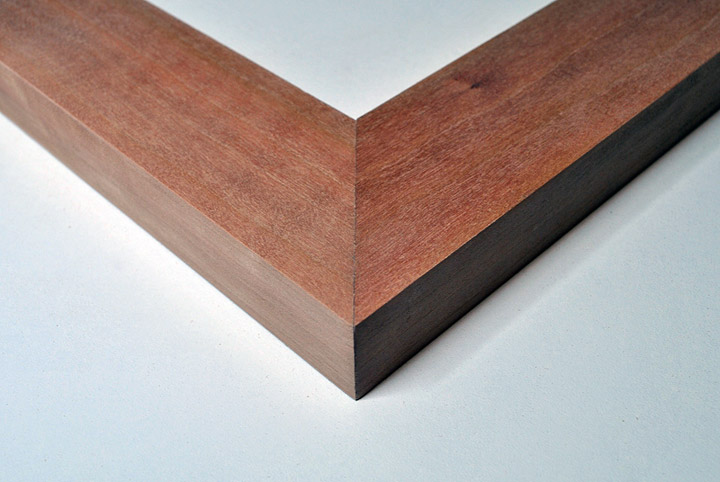

There are many ways of fastening pieces of wood together, some are purely functional such as butt joints, while others such as dovetails are functional as well as decorative.

Description of joining plywood to make longer sheets to be used in boatbuilding.

Fig. B: Butt joint. Butt joints have no recess, so you have to build up a layer of mud that’s thin enough and wide enough to blend into the surrounding flat surface.

The biscuit reinforced butt joint is a fairly recent innovation in butt joint construction. It is used primarily in carcase and frame construction. The biscuit is an oval shaped piece of specially dried and compressed wood, usually beech, which is installed in matching mortises in both members of the joint in a similar fashion to a loose or

Wood joints are an aspect of woodworking that involves attaching two different pieces of wood together to create a larger more complex structure. While some joints rely on more than just precise cuts to create a joint and use materials such as brackets or adhesives, other advanced forms of jointery

To make a simple square or rectangular frame, cabinet, box or drawer, using butt joints is very easy.

A description of eight types of wood joints and examples of what they can be used for

DT: Pupils can revise or learn about wood joints including; butt, mitre, halving, mortise & tenon, dowel, lap, housing and finger joints. Pupils can then try the ‘quiz time’ questions to test their joint knowledge.